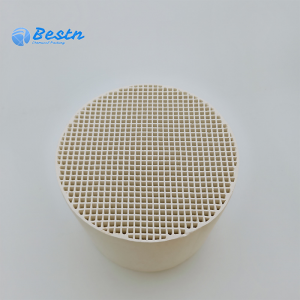

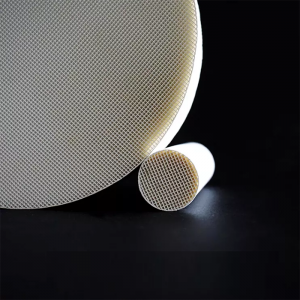

Panyimpenan Termal RTO RCO Keramik Honeycomb Kanggo Panas Recovery

Panyimpenan Termal RTO RCO Keramik Honeycomb Kanggo Panas Recovery

● Ngurangi mundhut termal saka gas exhaust, lan nambah efficiency

● Nambah suhu kobong teori, nambah kobong atmosfer, ketemu suhu dhuwur saka peralatan termal, nggedhekake aplikasi saka nilai calorific kurang, utamané sawetara aplikasi saka tungku jeblugan, nambah efficiency saka nilai calorific lan ngurangi emisi saka nilai calorific kurang gas batu bara.

● Ngapikake syarat-syarat ijol-ijolan panas ing hearths, nambah output saka peralatan, nambah kualitas produk lan Cut mudhun ing reinvesting ing peralatan /

● Ngurangi emisi exhaust saka peralatan termal, ngenthengake polusi udara lan nambah lingkungan.

● Resistance suhu dhuwur, resistance karat, resistance kejut termal apik, kekuatan dhuwur, kapasitas panyimpenan panas gedhe, konduktivitas termal apik, lan sapiturute lan efek nyimpen energi lan urip layanan sing nemen apik.

● Digunakake kanthi akeh ing kabeh jinis tungku pemanasan, tungku jeblugan panas, tungku perawatan panas, tungku retak, peralatan baking, tungku leleh, tungku soaking, tungku ketel lenga lan gas ing industri wesi lan baja, industri bahan bangunan, industri kimia, industri petrokimia , industri cat, industri peleburan logam non-ferrous.

| Sifat Keramik Honeycomb | |||||

| Item | Unit | Keramik Alumina Kab | Cordierite padhet | Cordierite | Mullite |

| Kapadhetan | g/cm3 | 2.68 | 2.42 | 2.16 | 2.31 |

| Akeh Kapadhetan | kg/m3 | 965 | 871 | 778 | 832 |

| Koefisien Ekspansi Termal | 10-6/k | 6.2 | 3.5 | 3.4 | 6.2 |

| Kapasitas Panas Spesifik | j/kg·k | 992 | 942 | 1016 | 998 |

| Konduktivitas termal | w/m·k | 2.79 | 1.89 | 1.63 | 2.42 |

| Thermal Shock Resistance | Max K | 500 | 500 | 600 | 550 |

| Suhu Softening | ℃ | 1500 | 1320 | 1400 | 1580 |

| Suhu Service maksimum | ℃ | 1400 | 1200 | 1300 | 1480 |

| Kapasitas Panas Rata-rata | w/m·k/m3·k | 0.266 | 0.228 | 0.219 | 0.231 |

| Penyerapan banyu | % | ≤20 | ≤5 | 15-20 | 15-20 |

| Tahan Asam | % | 0.2 | 5.0 | 16.7 | 2.5 |

| Parameter Keramik Honeycomb | |||||||

| Sakabèhé dimensi | Pola sel | Nomer Sel | Jembaré sel | Tembok njero | Tembok njaba | Area lumahing tartamtu m2/m3 | Fraksi Void |

| 150*150*300 | kothak | 5*5=25 | 26 | 3.05 | 3.5 | 146 | 76% |

| 150*150*300 | kothak | 13*13=169 | 9.3 | 2.05 | 2.5 | 310 | 65% |

| 150*150*300 | kothak | 25*25=625 | 5 | 0.95 | 1.5 | 582 | 69% |

| 150*150*300 | kothak | 32*32=1024 | 3.9 | 0.8 | 1.3 | 736 | 67% |

| 150*150*300 | kothak | 40*40=1600 | 3 | 0.67 | 1.3 | 892 | 66% |

| 150*150*300 | kothak | 43*43=1849 | 2.8 | 0.65 | 1.3 | 964 | 64% |

| 150*150*300 | kothak | 50*50=2500 | 2.4 | 0.6 | 1.1 | 1104 | 62% |

| 150*150*300 | kothak | 60*60=3600 | 2 | 0.5 | 1.1 | 1291 | 62% |

| 200*100*100 | Lingkaran | 20*9=180 | 8.5 | 2.3 | 2.5 | 280 | 51% |

| 150*100*100 | kothak | 36*24=864 | 3 | 1.1 | 1.2 | 734 | 52% |

| 150*100*100 | Hexagon | 35*20=700 | 4 | 1 | 1.2 | 687 | 65% |

| 150*100*100 | Hexagon | 10*6=60 | 12 | 4 | 4 | 210 | 50% |

| 150*100*100 | Hexagon | 35*20=700 | 3.5 | 1.5 | 1.5 | 570 | 50% |

| 150*100*100 | Lingkaran | 17*13=221 | 7.5 | 1.2 | 1.3 | 366 | 57% |

| 150*100*100 | Lingkaran | 33*19=627 | 4 | 1 | 1.3 | 568 | 53% |

| 150*100*100 | Lingkaran | 15*9=135 | 8.5 | 2.3 | 2.5 | 280 | 51% |

| 150*100*100 | Hexagon | 38*22 = 836 | 3.6 | 0.9 | 1.2 | 696 | 63% |

| 150*100*100 | kothak | 42*28=1176 | 2.6 | 1 | 1.1 | 815 | 53% |

| 100*100*100 | Hexagon | 7*6=42 | 12 | 4 | 4 | 224 | 52% |

| 100*100*100 | kothak | 31*31=961 | 2.65 | 0.55 | 0.7 | 1065 | 67% |

| 100*100*100 | kothak | 24*24=576 | 3 | 1.1 | 1.2 | 741 | 52% |

| 100*100*100 | Hexagon | 23*20=460 | 4 | 1 | 1.2 | 608 | 64% |

| 100*100*100 | Lingkaran | 10*9=90 | 8.5 | 2.3 | 2.5 | 280 | 51% |